Product Description

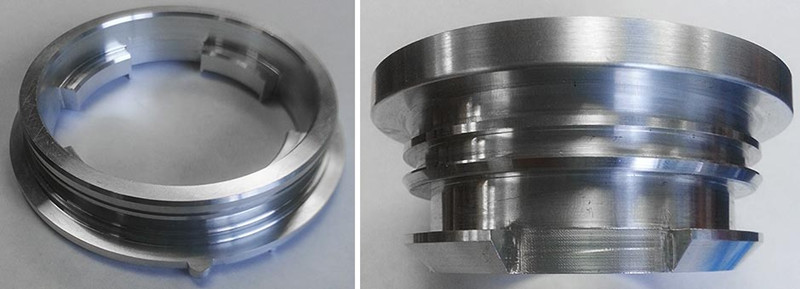

The investment casting process is fairly adapted to produce mid to highly complex metallic components. As a matter of fact, the usage of wax in the initial moulding stage contributes to produce parts with a smooth surface finish close to machined one (+- 125 RMS as cast) while this process enables the manufacturer to deliver parts with much more accurate dimensional tolerances than the most common sand casting process.

Then, the investment casting process is often selected as the optimal process to either develop new complex to highly complex parts or to convert weld parts into casting. Resulting in greater physical properties and cost-reduction vs the assembly of a few machined parts together.