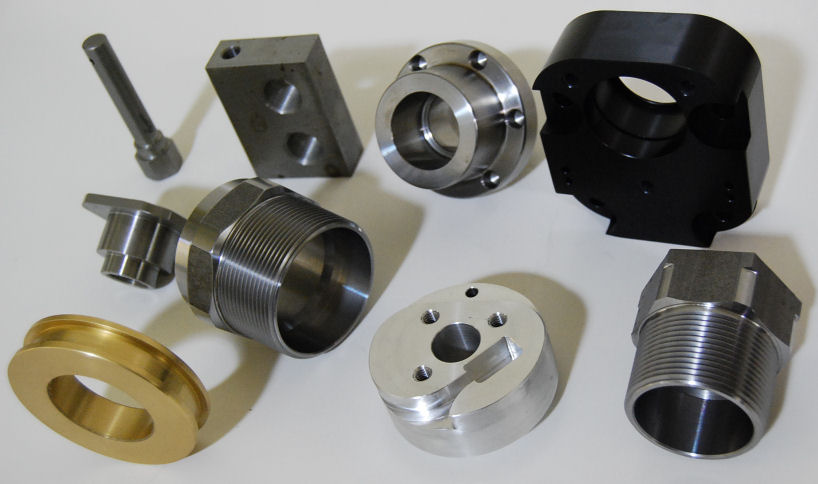

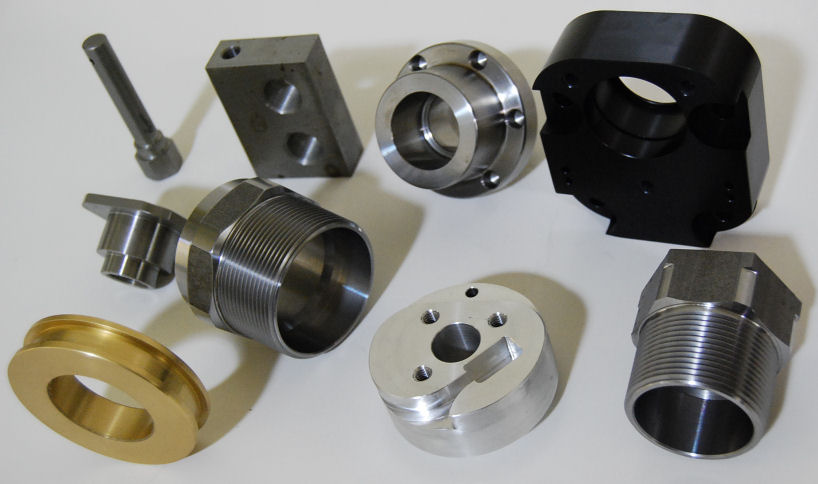

Product Description

The main advantage of cast steel is the design flexibility. The designer of the casting has the greatest freedom of design choices. This allows for complex shapes and hollow cross-section parts.The weight range of steel castings is larger. Little weight can be only a few dozen grams of molten mold precision castings. The weight of large steel castings goes up to several tons, dozens of tons or hundreds of tons.Steel castings can be used for a variety of working conditions. Its mechanical properties are superior to any other casting alloys, and a variety of high-alloy steel for special purposes. To withstand high tensile stress or dynamic load of components, it is important to consider pressure vessel castings. In low or high temperature, large and important part load key parts should give priority to steel castings. Product description Process : Investment Casting Material: Stainless Steel,Carbon Steel,Alloy Steel,etc Weight: 0.001Kg~30Kg Heat Treatment: Anneal,Quenching,Normalizing,Carburizing,Polishing,Plating, Painting,etc Machining Equipment : CNC Center , CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc Measuring Tool : CMM , Projector, Vernier Caliper, Depth Caliper, Micrometer,Pin Gauge, Thread Gauge , Height Gauge,etc