We adopted advanced silica colloid process for OEM precision casting to manufacture castings with no or less extra metal. Technical stability analysis and improvement method are used for production process control. 100% inspection for each process and advanced instruments (projector, tri-coordinator, spectra) help to produce qualified castings.

Our main OEM Precision casting products are castings in stainless steel, carbon steel, alloy steel products serve for many trade as food, chemical, medicine, marine, automatic, architecture etc. 90% for exporting to America, Europe and some Asia countries.

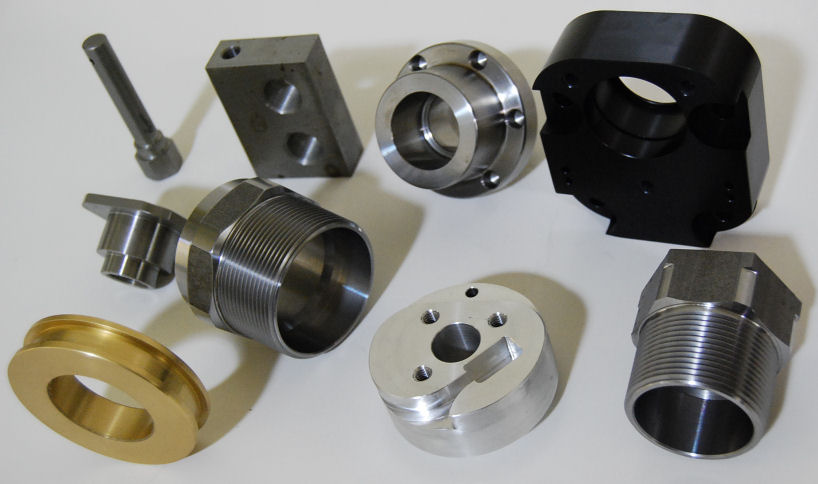

Main machines for after-casting process such as machining centers, CNC lathe, polishing machine could supply machining, hand polishing, assembly.

Our QC department and development department offer material inspection, strength test, hardness test, magic powder test and X-ray test. Tri-coordinate instrument and projector can help to measure exact dimensions. GO&NO GO gauge will be 100% used to assure high quality requirement.

Products show

Process

Process  Our factory

Our factory