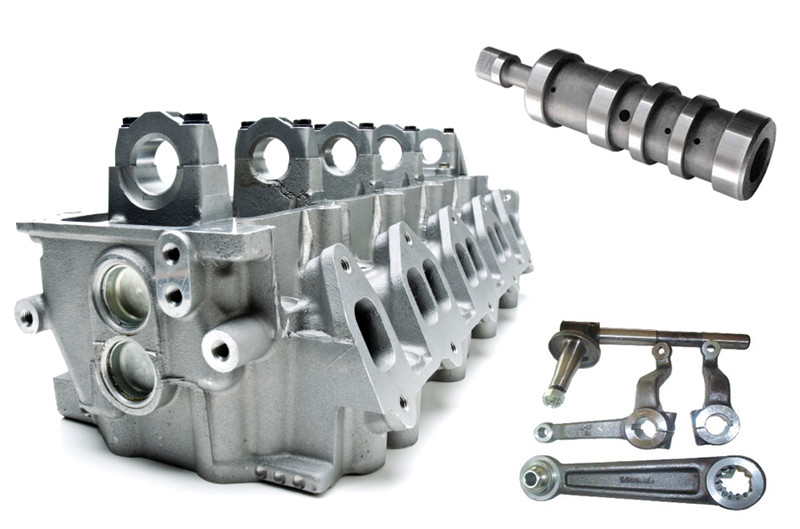

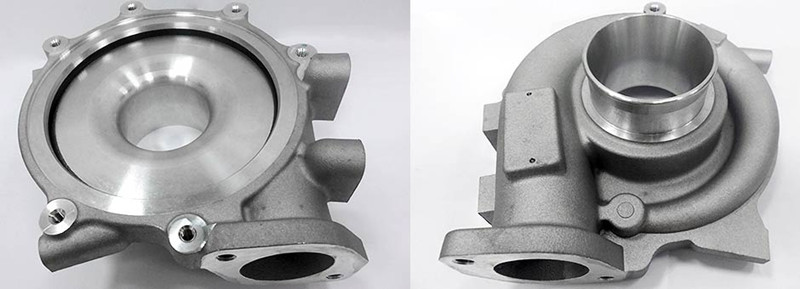

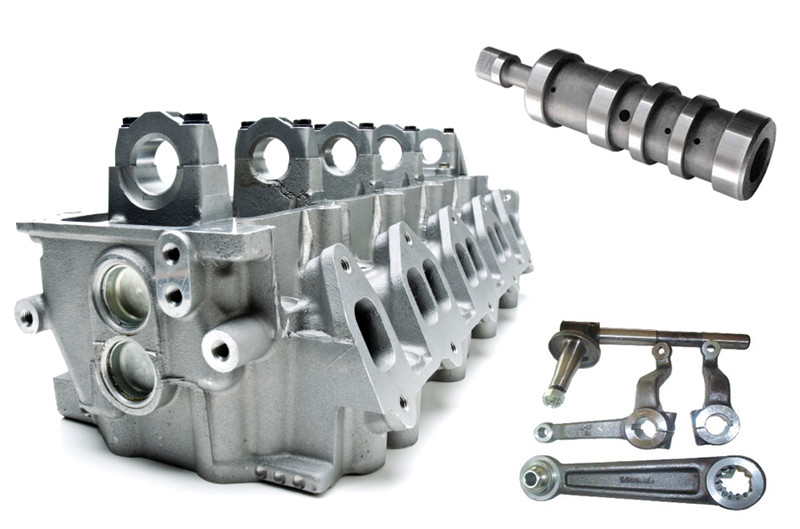

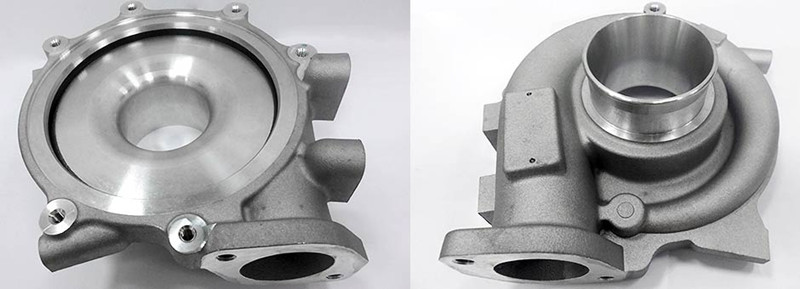

Product Description

We produce zinc die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly. we offer a broad range of zinc die casting surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish. The industries include automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others. Zinc die casting is a metal casting process characterized by pressuring molten metal into the mold cavity. The mold cavity is created using two hardened tool steel molds that are machined to the net shape or near net shape of the zinc die casting parts. Zinc die casting process allows products to be made with high degree of accuracy and repeatability. The Zinc die casting process can also produce fine details such as textured surfaces or names without requiring further processing. Advantages of Zinc Die Casting Products show

What Is Zinc Die Casting?

- Great tool life

- Precision tolerance

- Superior thermal conductivity

- Fast cycle time

- Corrosion resistance

- Superior for decorative finishing

- Low energy cost