Product Description

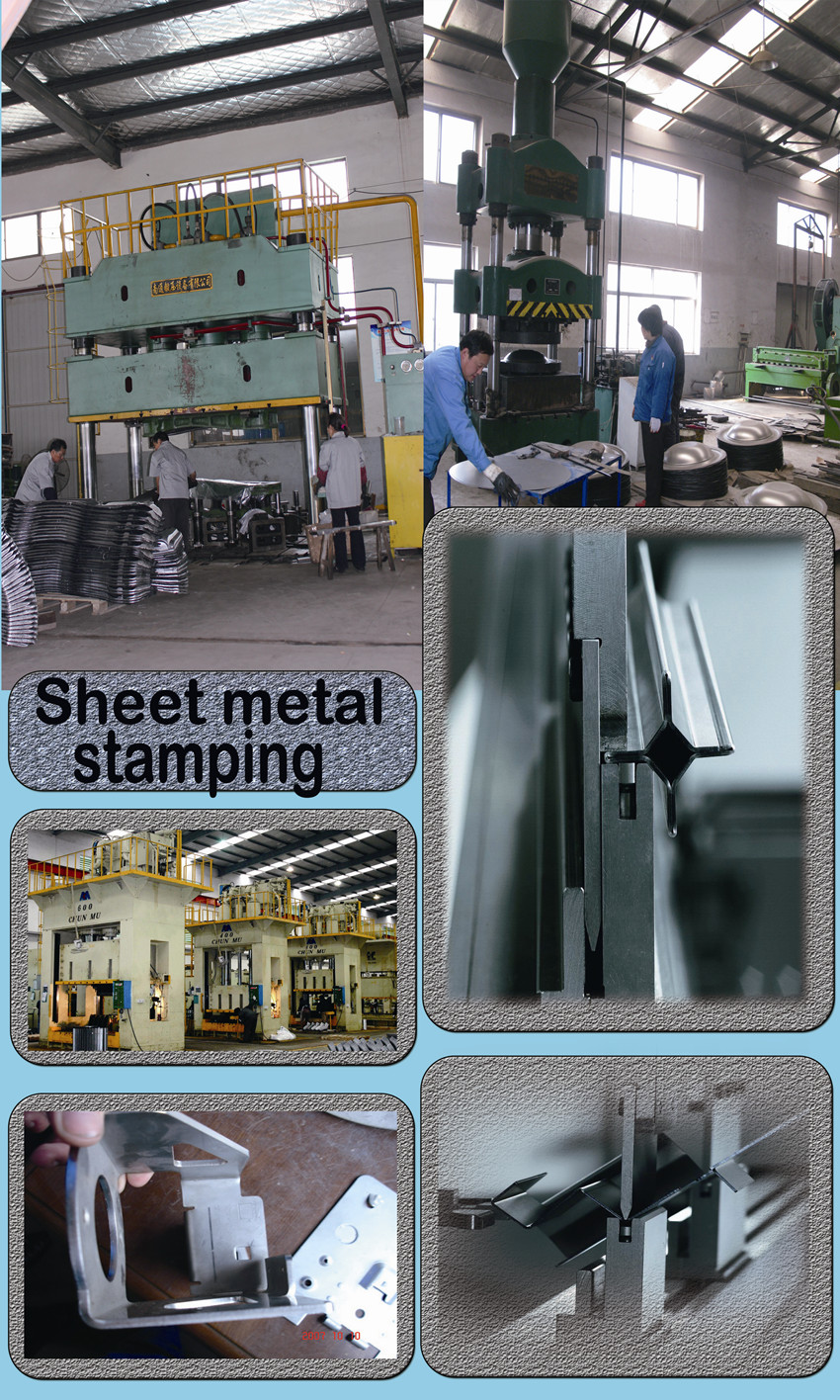

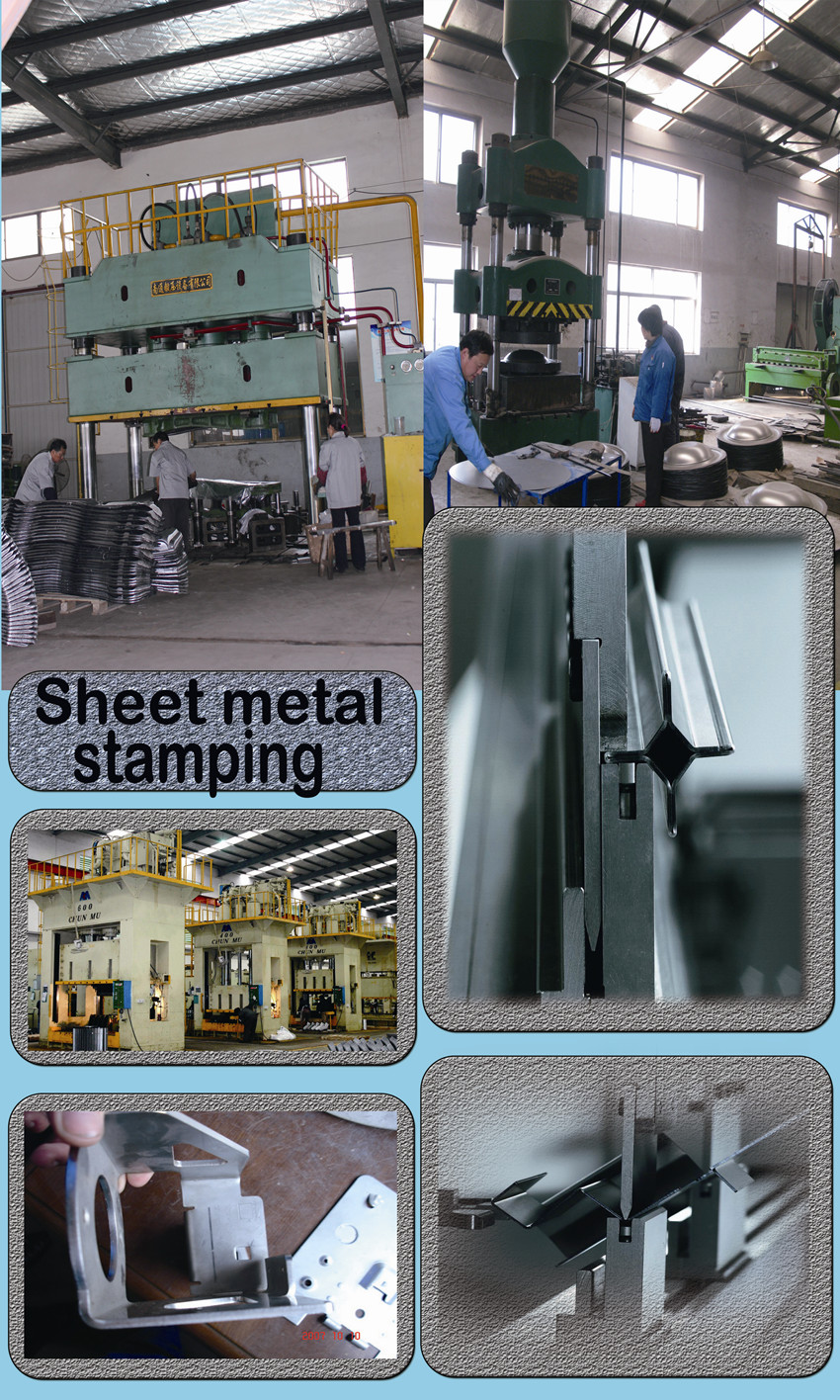

The company mainly produces sheet metal, plastic injection mould, power cabinet, chassis, cabinets, network cabinets, advertising cabinets, computers, die casting, communications and other products supporting hardware, assembly, etc. We have also R&D of metal mould design and manufacturing, as well as various types of metal stamping parts, LED frame, rear shell, metal base. Our equipment including Punching machine, hydraulic press, stretch machine, shears, bending machine, welding machine, laser cutting machine, painting production line, phosphating production line, continuous die stamping production line ; universal testing machine, deep-drawing microscope, salt spray test machine, hardness tester, thickness meter, sheet metal projectors. General product information Material availableCarbon steel(CRS/SPCC,SECC,etc),Stainless steel, spring steel, Bronze(berylium,phosphor,etc), brass, copper alloy,aluminum alloy, tinplate,nickel silver, plastic Surface treatment availablezinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush,wire drawing,etc. Metal processing availableStamping parts:tooling making, samples approval, cutting,stamping, punching,tapping,welding,bending and forming, finishing, assembly CNC parts:CNC lathe milling, CNC lathe turning, drilling, tapping, finishing, assembly, packing SpecificationOEM/ODM,make per customer's drawing or sample Package availablepolybag inside export carton outside or according customer's requirement, blister and Tape and reel package available. ToleranceStamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm Service availableBefore mass production, we supply pre-production samples for customer final confirmation, tooling maintenance and tooling slight change free Documents availableISO certificate, material SGS testing reports, products certificate, company SGS report, COC report CertificateISO9001:2008 approval, SGS compliance Products show