The die casting process can create the components necessary for industries all across the spectrum. But choosing the type of metal alloy to die cast may not always be a totally straightforward choice. There are certainly advantages and disadvantages to each type of die cast material, but today, we're going to focus on aluminum die casting. Armed with this information, you'll be able to make an educated decision on which type of die cast material will work best for your needs.

Properties Of Die Cast Aluminum Aluminum actually accounts for more than 80% of all die cast parts, and there are several good reasons for that. It didn't become the most popular die cast alloy by accident, after all. While aluminum die casting may not be perfectly suited for every single project, it has a widespread appeal due to its properties. When used in die casting, aluminum possesses the following qualities.

- It's lightweight

- It's strong

- It has a high melting point

- It has good thermal and electrical conductivity

- It's recyclable

- It's non-magnetic

A few of these features (like aluminum's strength and the fact that it's recyclable) are shared by other metal alloys. But aluminum is quite unique in that it's cast through a cold chamber method, rather than a hot chamber process. This is due to its higher melting point.

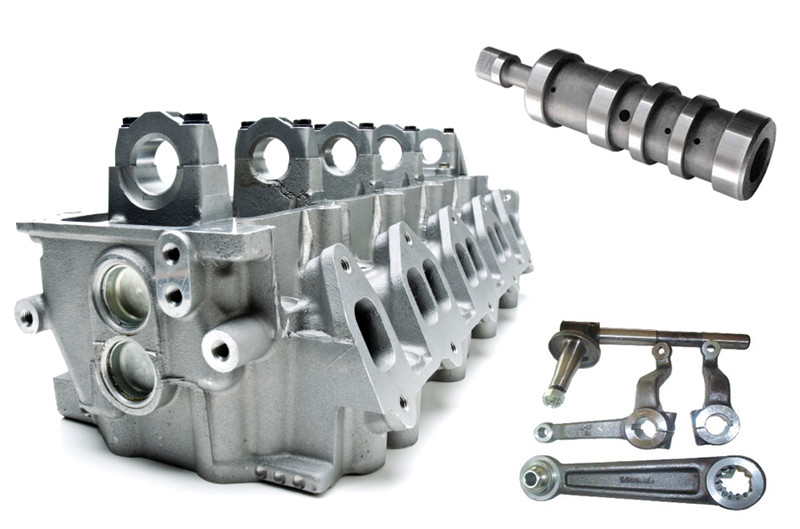

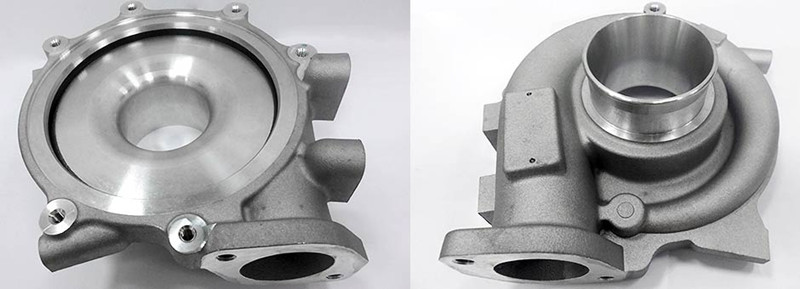

Products show