Product Description

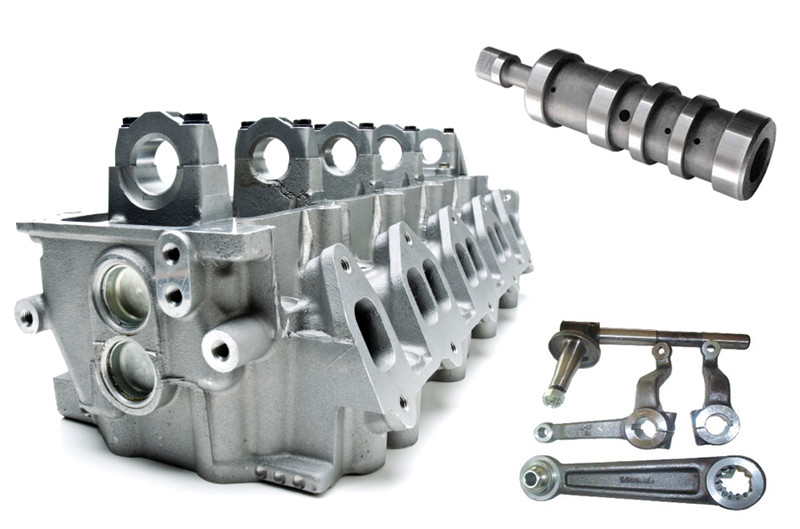

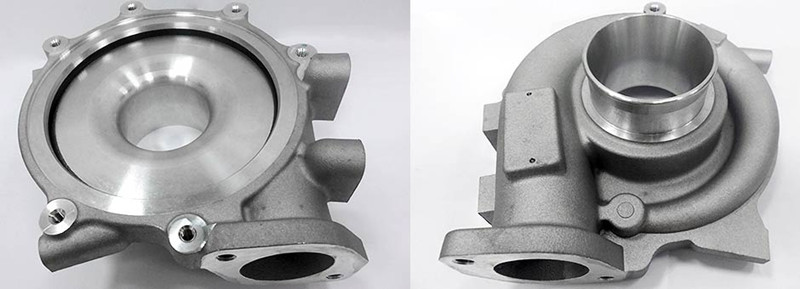

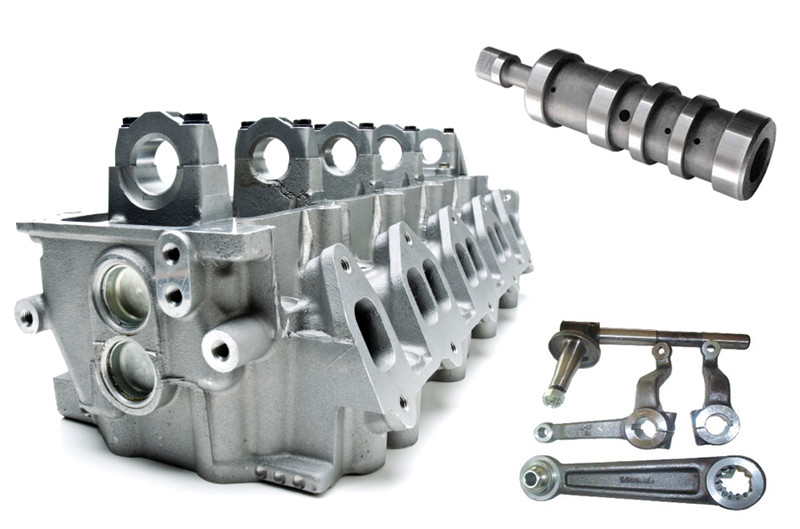

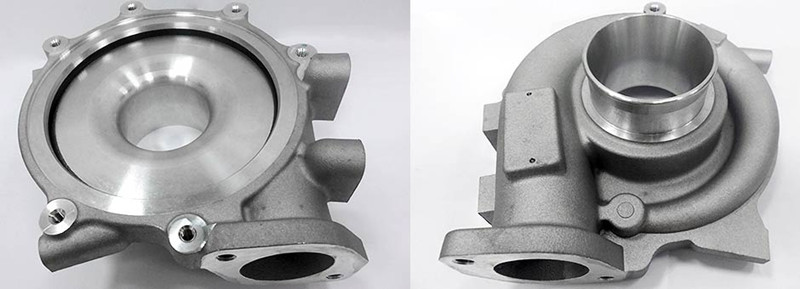

The aluminum die casting process refers to our high pressure die casting process that used for thin wall thickness parts. High pressure aluminum die casting is a process in which molten aluminum alloy is injected into casting molds under high pressure at a controlled temperature. After casting, the aluminum die casting blank will be stamped to remove flash around the edge of product. The whole aluminum die casting production process is fast and inexpensive than other casting methods. Below is the video which shows how our high pressure aluminum die casting process is made in our company. Products show

What Is Aluminum Die Casting?

Aluminum die casting is a manufacturing process for producing accurately dimension, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. The aluminum die casting process involves the use of a furnace, aluminum alloy, die casting machine, and die. Dies that usually constructed with long-lasting, quality steel have at least two sections to permit removal of castings.Advantages of Aluminum Die Casting

- Simple or complex shapes

- Thin wall thickness

- Light weight

- High rates of production

- Corrosion resistance

- Monolithic – combine multiple functions in one

- Efficient and economical alternative to other processes