Product Description

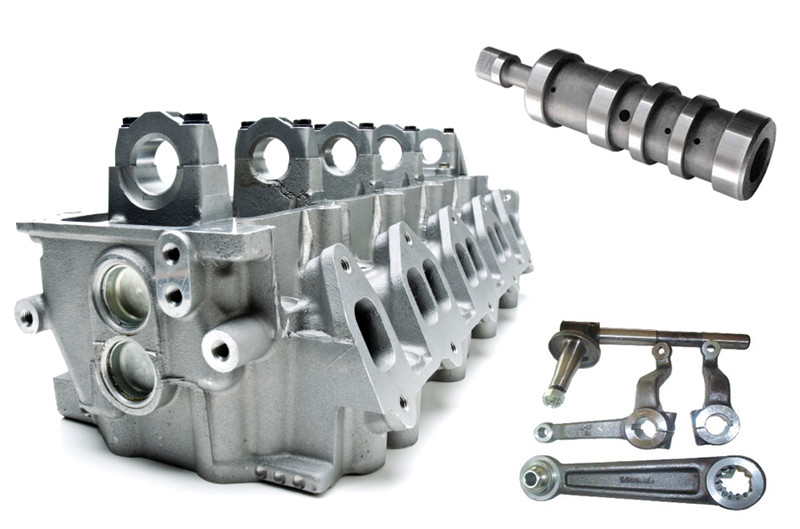

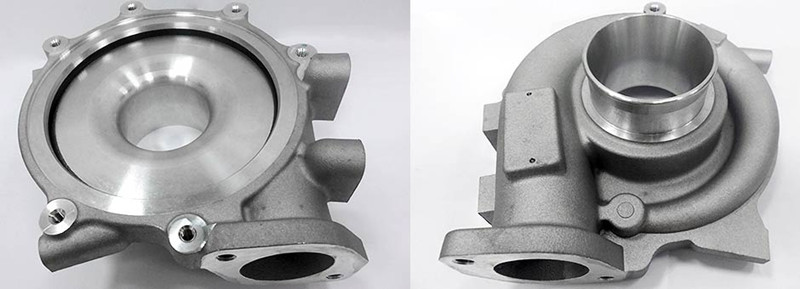

Hebei Mingda provides superior quality aluminum die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.

Aluminum die casting is a manufacturing process for producing accurately dimension, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. The aluminum die casting process involves the use of a furnace, aluminum alloy, die casting machine, and die. Dies that usually constructed with long-lasting, quality steel have at least two sections to permit removal of castings. Aluminum die casting is a great choice for manufacturing parts with the highly valued combination of light weight and superior strength at a high rate. With die casting machines ranging from 180 up to 2,000 metric tons and CNC machine centers, we can produce aluminum die casting parts from a few grams to more than 40 pounds with superior quality ready for assembly. For aluminum die casting parts with requirements of esthetical, functional, or protective coatings, we also offer a broad range of surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish.

What Is Aluminum Die Casting?

Advantages of Aluminum Die Casting

- Simple or complex shapes

- Thin wall thickness

- Light weight

- High rates of production

- Corrosion resistance

- Monolithic – combine multiple functions in one

- Efficient and economical alternative to other processes