Hebei Mingda International Trading Company, a leading trading company specializing in castings, forgings, and machinery parts, has announced that the global aluminum casting market is set to grow at a steady pace over the next few years. The market is expected to be valued at USD 97.36 billion by the end of 2026.

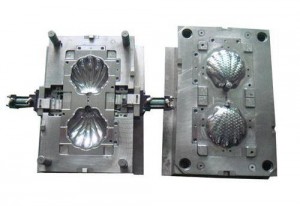

Aluminum casting is a manufacturing process where molten aluminum is poured into a mold and allowed to cool and solidify into a desired shape. The process can be divided into three broad categories: die casting, permanent mold casting, and sand casting.

Die casting is a process where molten metal is injected into a mold under high pressure, resulting in a very accurate and precise casting. Permanent mold casting, on the other hand, is a method where molten metal is poured into a permanent mold and allowed to cool and solidify. Finally, sand casting involves creating a mold from sand and pouring molten metal into it.

The global aluminum casting market can be segmented on the basis of end-use sector into automotive, aerospace and defense, building and construction, electrical and electronics, industrial, and others. Of these, the automotive sector is expected to be the largest end-use segment, accounting for a significant share of the market.

The growth of the automotive sector can be attributed to the increasing demand for lightweight vehicles with better fuel efficiency and lower emissions. Aluminum has several properties that make it an ideal material for the automotive industry, such as high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance.

The aerospace and defense industry is another key end-use sector for the aluminum casting market. Aircraft manufacturers are increasingly using aluminum castings in the production of aircraft components such as engines, landing gears, and structural parts. The use of aluminum castings has several advantages, such as increased strength, durability, and reduced weight, which can help to increase fuel efficiency and reduce emissions.

The building and construction industry is also expected to drive growth in the aluminum casting market. Aluminum castings are used in the production of structural components such as window frames, doors, and roofing systems. The use of aluminum in construction can help to increase energy efficiency, reduce maintenance costs, and improve the overall appearance of buildings.

On the basis of region, the global aluminum casting market can be divided into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific is expected to be the largest market for aluminum castings, accounting for a significant share of the market. This can be attributed to the presence of several established automotive and aerospace industries in the region.

North America and Europe are also expected to be key markets for aluminum castings, driven by the growth of the automotive and aerospace industries. The Middle East & Africa and Latin America are expected to witness steady growth in the aluminum casting market over the forecast period.

In conclusion, the global aluminum casting market is poised for steady growth over the next few years, driven by the increasing demand from the automotive, aerospace and defense, building and construction, and electrical and electronics industries. The use of aluminum castings can help to increase energy efficiency, reduce maintenance costs, and improve the overall appearance of products. With the growth of these industries, the demand for aluminum castings is expected to increase, driving growth in the global market.